- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

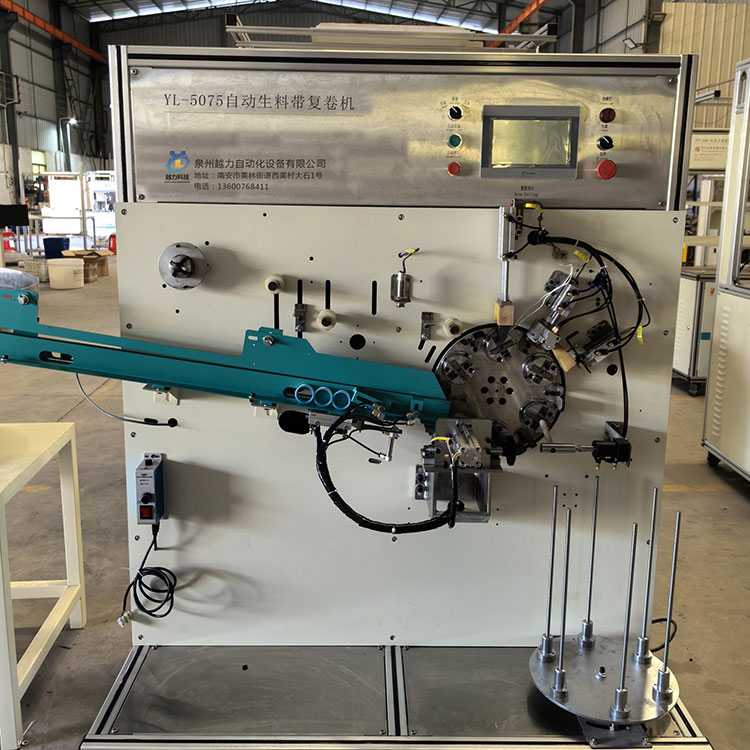

PTFE Tape Auto Winding Machine

YueLi is PTFE Tape Auto Winding Machine manufacturers and suppliers in China. Fully automatic raw material tape unwinding machine PTFE rewinder PTFE is an efficient and convenient raw material tape unwinding equipment. This equipment uses advanced polytetrafluoroethylene (PTFE) material, which has excellent high temperature resistance, corrosion resistance and wear resistance. It can be widely used in pipe sealing, thread fastening and other fields in chemical, pharmaceutical, food, electronics and other industries. .

Send Inquiry

Fully automatic raw material tape unwinding machine PTFE winding machine PTFE

PTFE Tape Auto Winding Machine introduction

PTFE Tape Auto Winding Machine is an efficient and convenient raw material tape unwinding equipment. This equipment uses advanced polytetrafluoroethylene (PTFE) material, which has excellent high temperature resistance, corrosion resistance and wear resistance. It can be widely used in pipe sealing, thread fastening and other fields in chemical, pharmaceutical, food, electronics and other industries. .

PTFE Tape Auto Winding Machine Features

1. Fully automatic operation: This equipment adopts advanced PLC control system, which can realize fully automatic control, reduce manual operation costs and improve production efficiency.

2. Efficient rolling: The equipment adopts a precise mechanical structure, which can quickly and accurately complete the rolling work of raw material tape and improve production efficiency.

3. High-quality materials: This equipment uses polytetrafluoroethylene (PTFE) material, which has excellent high temperature resistance, corrosion resistance, and wear resistance, and can extend the service life of the equipment.

4. Safe and reliable: The equipment adopts multiple safety protection measures to ensure operator safety and stable product quality.

5. Easy to maintain: The equipment has a simple design and is easy to maintain, which can reduce maintenance costs.

Instructions for use

1. Place the raw material belt on the feeding device, and adjust the width and height of the feeding device so that the raw material belt can smoothly enter the rolling mechanism.

2. Start the equipment and adjust the rotation speed and tension of the rolling mechanism so that the raw material belt can be rolled evenly.

3. When the rolling is completed, the equipment will automatically stop and the rolled raw material tape can be taken out.

4. Carry out regular maintenance and upkeep on the equipment to ensure normal operation of the equipment.

Precautions

1. Check whether the equipment is normal before use, and deal with it in time if there are any abnormalities.

2. Wear protective glasses and gloves during operation to prevent accidental injuries.

3. It is strictly prohibited to touch the running parts when the equipment is running to avoid danger.

Main product specifications and parameters:

|

total power |

power supply |

work pressure |

Winding speed |

Yield |

Machine size (length, width and height) |

Machine net weight |

|

500W |

220V/50Hz |

0.6-0.7MPa |

4-5.55/time |

500-650 pieces/hour |

(2100*815*1500)mm (including vibrating plate) |

300KG (including vibrating plate) |

our service:

1. Reply your inquiry in 24 working hours.

2. Experienced staffs answer all your questions in fluent English.

3. Customized design is available. UEM&UBM are welcomed.

4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

5. Special discount and protection of sales are provided to our distributor.

6. Professional factory : We are manufacturer, specializing in producing all kinds of machinery for more than 20 years, competitive with good quantity.

7.Sample: We can send out sample for test in one week if the order quantity is big enough. But the shipment charges is usually paid by your side, the charges will be rebounded when we have formal order.

8.As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature. Welcome to contact us or visit our company.

our company:

Quanzhou Yueli Automation Equipment Co., Ltd was founded in 2013, which covers an area of 3000 square meters. The company is located at the China Plumb Town--Nanan, Fujian. It is a production enterprise lead by drilling tapping compound machine, drilling tapping centers and drilling tapping milling process center. The company is committed to serving various of industries such as sanitary ware, fire protection valves, hardware, electrical hardware, aerospace, machine manufacturing and so on.

Quanzhou Yueli Automation Equipment Co., Ltd has developed from a simple assembly manufacturing industry to be a machining manufacturer which collects research and development, production, sales and service. It owns CNC gantry rail grinder machine, boring mill, milling, digging, polishing compound machine and other advanced test equipment. Our company product is from sales, service network throughout the China domestic market. They are exported to foreign countries and regions.

We continue to innovate and strive for perfection in our products. We are specialized at quality, focus on the spirit, dedicated service to acquire the perennial support and profound affection from our customers.

In the future, we will continue to pay attention to the needs of users, constantly improve the professional level, the quality of science and technology. Win the market with the quality. We are willing to join hands in creating our brilliant future.