- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

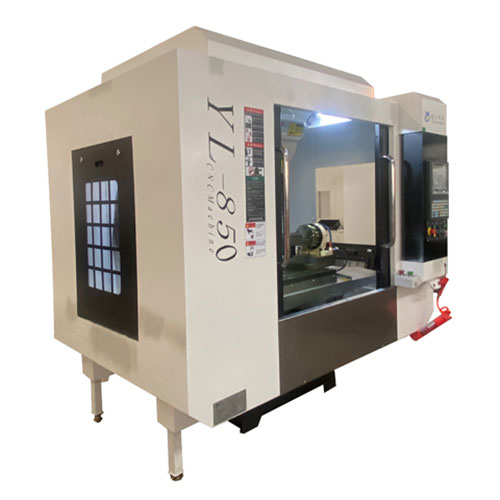

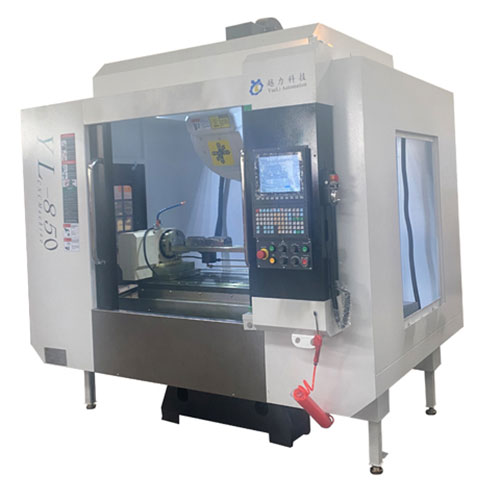

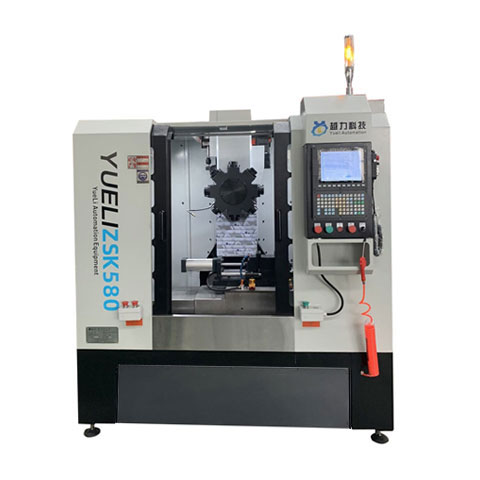

CNC Drilling Tapping Machining Center Machine

YueLi warmly welcome you to wholesale CNC Drilling Tapping Machining Center Machine from our factory. Our products are CE certified and currently have a large amount of factory inventory. We will provide you with good service and factory discounted prices.

Send Inquiry

Technical parameters of vertical drilling and tapping center

YueLi is a professional CNC Drilling Tapping Machining Center Machine manufacturers and suppliers in China. If you interested in products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.

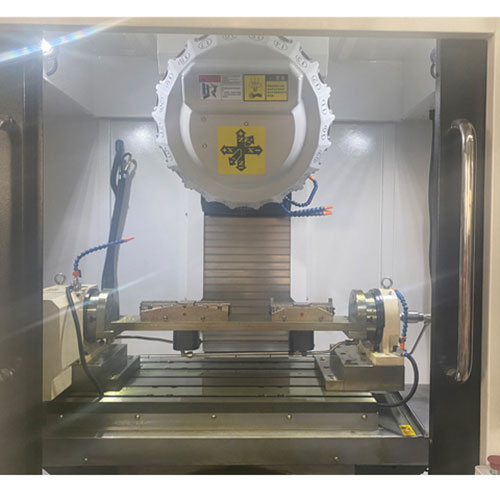

1,With the function of machining center, but also faster than the machining center efficiency of 21 tool drilling and tapping center, program control part of the use of Taiwan Yitu CNC control system, secondary development system, can change the tool and the workpiece tool synchronously, man-machine friendly dialogue, easy to operate.

2, suitable for large and medium batch parts processing, one-time clamping completion, high efficiency, good accuracy.

3, 850 machining center structure, bamboo head type tool change mode, with Beijing super synchronous main servo motor with frequency conversion, Delta servo feed motor, improve the surface roughness of the workpiece thread, to ensure processing accuracy and efficiency.

4, power head components using Taiwan brand, precision grinding, good wear resistance, long life.

5, million figure numerical control system, according to the need to set the corresponding feed speed, after the use of equipment, screw wear, the system itself with the tool function.

6, each mechanical sliding surface adopts centralized automatic lubrication device to ensure the service life of the machine.

7. The sliding table movement is driven by servo motor, and multiple coordinates can be set when moving into place digitally, with high positioning accuracy, small vibration and fast response.

8, the processing process, through the touch screen display workpiece processing in place, failure alarm function.

9, fully enclosed protection, to ensure personal safety, improve the processing environment.

|

item

|

unit

|

Technical parameter |

||

|

workbench |

Table size |

mm |

700*420 |

|

|

Maximum allowable load |

kg |

300 |

||

|

T-slot size |

mm |

3*14*100 |

||

|

Processing range

|

Travel: X axis |

mm |

700 |

|

|

Travel: Y-axis |

mm |

500 |

||

|

Travel: Z axis |

mm |

420 |

||

|

Distance from spindle end face to work surface |

mm |

145-495 |

||

|

Distance from spindle center to column |

mm |

420 |

||

|

Principal axis

|

Spindle form |

|

Straight-knot form |

|

|

revolution |

rpm |

20000 |

||

|

Feed

|

Cutting feed speed range |

|

|

|

|

Fast move |

X-axis |

m/min |

48 |

|

|

Y-axis |

48 |

|||

|

z-axis |

48 |

|||

|

Knife library (optional) |

Tool storage capacity |

|

21T |

|

|

Maximum tool diameter (adjacent space) |

mm |

60(80) |

||

|

Maximum tool length |

mm |

250 |

||

|

Maximum tool weight |

kg |

3 |

||

|

Tool change time (near tool) |

Sec |

1.6 |

||

|

Tool change mode |

Mechanical beater |

|||

|

Positioning accuracy XYZ three axes |

mm |

±0.005/300 |

||

|

Repeat positioning accuracy XYZ three axes |

mm |

±0.003/300 |

||

|

Required air pressure |

Kgf/cm² |

6 |

||

|

Required gas flow |

m³/min |

0.15 |

||

|

Net weight of optical machine |

kg |

250 |

||