- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

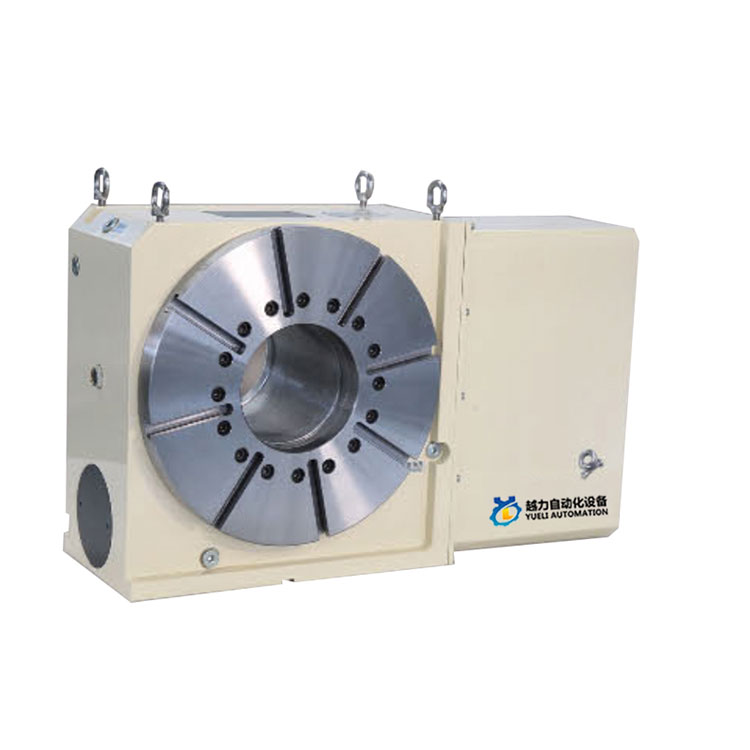

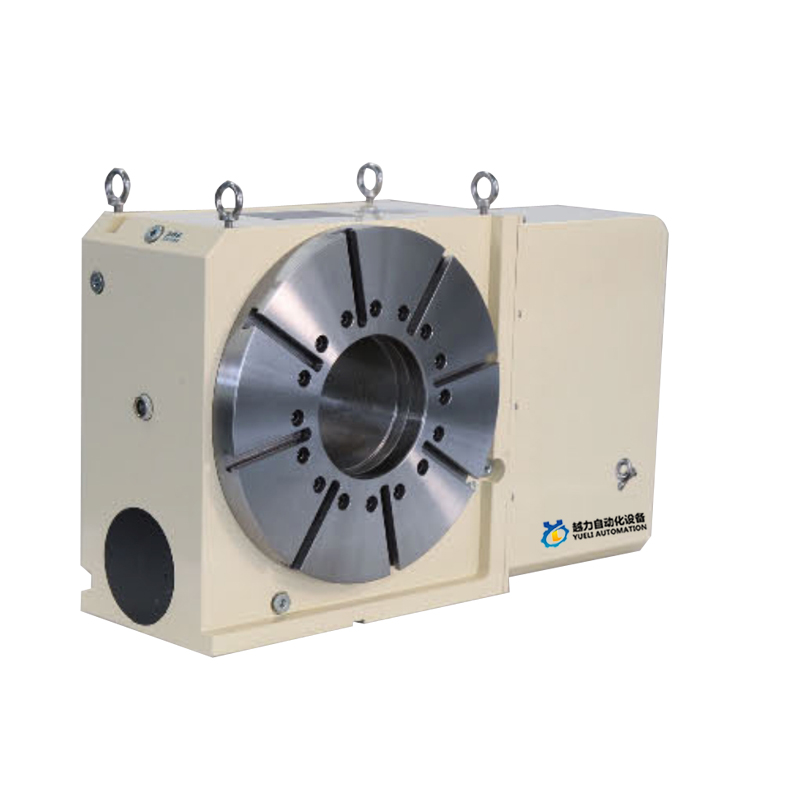

320 Four-axis CAM Turntable

YueLi is 320 Four-axis CAM Turntable manufacturer and supplier in China.

Send Inquiry

Yueli 320 four-axis CAM turntable

CAM type zero back backlash CNC rotation

Buy Discount Quality 320 Four-axis CAM Turntable with Low Price made in China. YueLi is 320 Four-axis CAM Turntable manufacturer and supplier in China.

Cam-roller transmission structure is adopted inside the product.

CAM shaft needle roller bearing precompression no gap rolling drive.

No sliding friction, continuously maintain no gap characteristics.

High accuracy of forward and reverse motion repetition.

High rigidity, high efficiency.

Does not cause poor accuracy due to temperature rise.

No need for regular calibration and adjustment.

Working principle and characteristics of cam-type CNC turntable

Principle of preloading

Compared with the traditional worm gear type NC turntable, the grating CAM type NC turntable has higher precision

Operating characteristics of degree, high speed, zero back clearance and heavy load. Input axial cams

The needle roller bearing on the output shaft turret of the constant speed driving curved surface is precompressed rolling contact transmission,

To achieve zero back backlash and higher speed operation, due to the rolling transmission almost zero

Friction movement, so that the mechanism can maintain no backbacklash transmission, high precision positioning, and no need

Regular calibration and adjustment work should be done. Lattice CAM type CNC turntable, Han out of the shaft use

The large bearing is arranged on the round outer wall of the shaft, and the two ends of the CAM input shaft are set with double bearings.

It also enhances the stability and load capacity of the turntable, and can better cope with the processingHigh speed and heavy cutting force, improve machining accuracy, efficiency and reduce costs.

Comparison of mechanism characteristics of CAM type zero back backlash NC turntable

|

No. |

Item |

Roller CAM Driyer 1M |

Worm Gear Type |

|

1 |

Drive type |

Ccw Output Angle |

- CCWa Outout Ang 360 |

|

2 |

Drive status |

Rolling contact |

Slide contact |

|

3 |

Material:Hardness of the contacpa |

Cam shaft:Hardening steel; HRC60 |

Worm shaft: Hardening steel; HRC60 |

|

Cam followers;Bearing steel; HRC60 |

Worm gear; Phosphor bronze; HB90 |

||

|

4 |

Preload |

○YES |

X N0 |

|

5 |

Transmission efficiency |

〇Higher |

△Lower |

Positioningtime 90° (Example)

|

|

Item N0. |

Competltor |

|

|

Release spindle clamping |

|||

|

Acceleraion |

|||

|

Linear rotary movement |

Linearrotarymovement |

||

|

Decelerate |

Decelerate |

||

|

Machining release |

Machining release |

||

|

Clamp spindle |

Clamp spindle |

||

|

Cycletime |

Cycletime |

||

|

Speed capacity |

Rigidity |

|

|

|

Durability |

3 Roller Bearing |

|

|

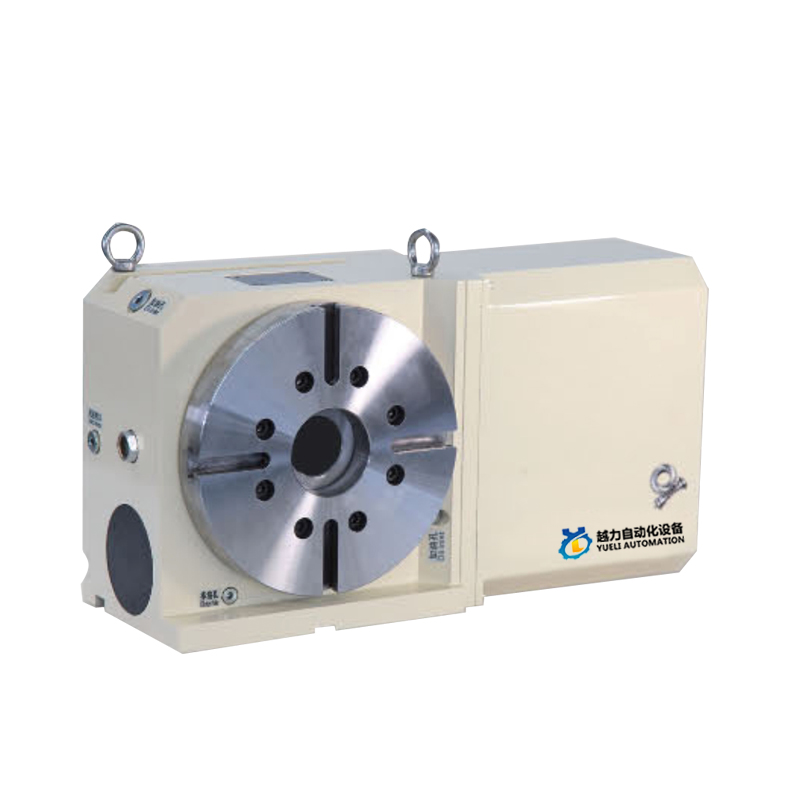

Yueli320 Reference data

|

CODE NO |

UNIT |

Yueli320 |

|

|

Table diameter |

φmm |

320 |

|

|

Center height |

mm |

210 |

|

|

Spindle hole |

φmm |

110 |

|

|

T slot width |

mm |

14 |

|

|

Guide key width |

mm |

18 |

|

|

Servo motor |

FANUC |

β22 |

|

|

MITSUBISH |

HF204 |

||

|

Min increment |

|

0.001° |

|

|

Gear ratic |

|

1:60 |

|

|

Max.rotation speed(3000 rpm) |

rpm |

40 |

|

|

Output rate torque |

kg/m |

100 |

|

|

Hydraulic resource pneumatic/hydraulic |

kg/m² |

30 |

|

|

Output torque at brake |

kg/m |

100 |

|

|

Indexing accuracy |

sec |

15 |

|

|

Repeatability |

sec |

4 |

|

|

Product quality |

kg |

116 |

|

|

Allowable worweight |

vertical |

kg |

150 |

|

horizontal |

kg |

300 |

|

|

vertical tailstock |

kg |

300 |

|

|

Allowableload |

↓F |

kgf-m |

2000 |

|

|

F*L kgf-m |

260 |

|

|

F |

F*L kgf-m |

200 |

|

Yueli320 Dimensions of the turntable