- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

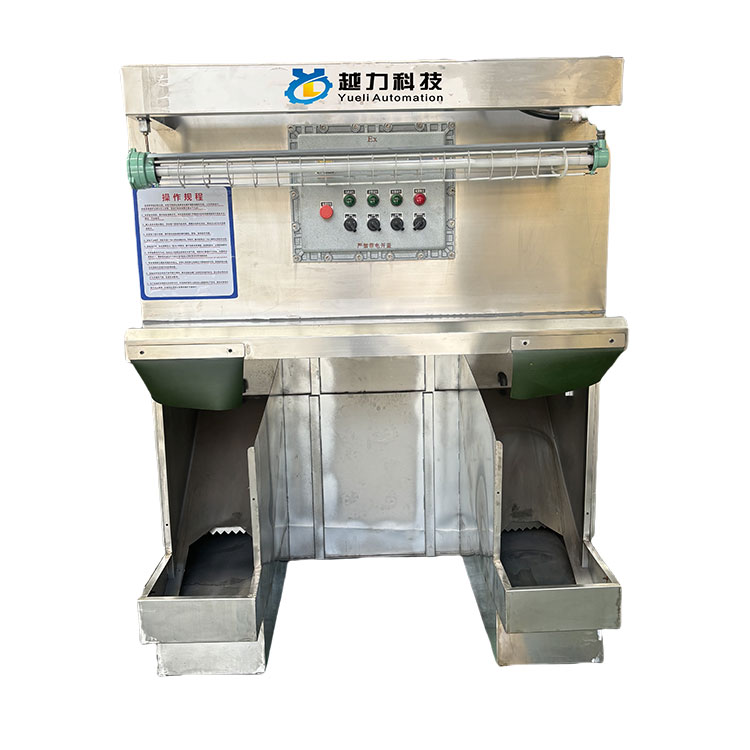

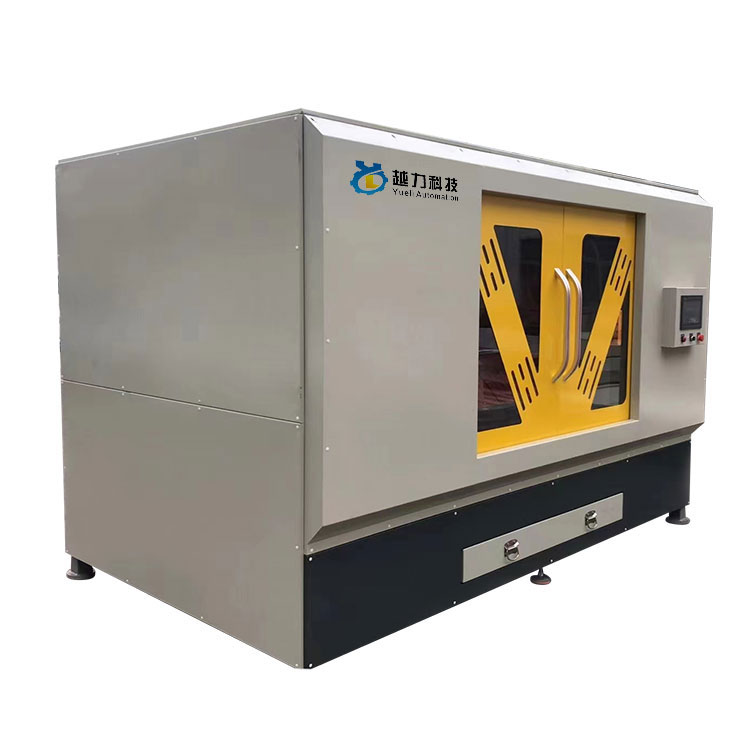

Mobile Dust Removal Equipment

As one of professional Mobile Dust Removal Equipment manufacturer in China, YueLi would like to provide you Mobile Dust Removal Equipment. And we will offer you the best after-sale service and timely delivery.The purified gas enters the upper box from the inside of the filter material and is then discharged into the atmosphere through the fan.

Send Inquiry

The Mobile Dust Removal Equipment is a dry dust collector, and its structure consists of an upper box, a lower box, a pulse system, an electric control system, a fan, and a discharge port. When the dust-laden gas enters the dust collector, due to the instantaneous reduction of wind speed, inertial collision, natural sedimentation, etc., larger particles fall directly into the ash box, and other dust particles rise with the airflow into the filter material layer of the lower box. After being filtered by the filter cartridge/bag, the dust particles are retained on the outside of the filter cartridge/bag. The purified gas enters the upper box from the inside of the filter material and is then discharged into the atmosphere through the fan. As the filtering process continues, the dust accumulated on the outside of the filter cartridge continues to increase, causing the resistance of the dust collector itself to gradually increase. When the pulse cycle reaches the preset time, the dust cleaning controller sends a pulse signal, causing the pulse valve to release 0.5-0.8MPa compressed air at the moment of action, so that the dust accumulated outside the filter cartridge falls off, and the dust that forms agglomerates falls into the ash hopper and is regularly shoveled out and cleaned manually.

Equipment advantages:

1. The equipment has a compact structure, small footprint, easy to move, simple maintenance, and will not cause secondary pollution.

2. The system is safe and reliable, with stable performance. Most wearing parts have a life of more than 2 years and low operating costs.

3. The suction force is large, the emission concentration is less than 20mg/m³, and an ordinary muffler is installed at the outlet, with a noise of about 75db.

4. The device can be selected according to different working conditions.

5. The equipment has a design life of more than 15 years.

Equipment parameters:

| Model | Parameters | |

| 1 | Dust removal fan power | 4kw |

| 2 | Noise (dB) | ≤75db (designed sound insulation device) |

| 3 | Number of bags (sets) | 40 |

| 4 | Filter bag specifications | Φ135×1000mm |

| 5 | Number of filter bag chambers (chambers) | 1 |

| 6 | Filter bag material | Water-repellent and oil-proof needle felt |

| 7 | Filter bag withstand temperature (℃) | ≤120 |

| 8 | Outlet emission concentration | ≥ 20mg/Nm3 |

| 9 | Equipment resistance (Pa) | 900-1100 |

| 10 | Dust removal efficiency | ≥99.9% |

Dust collector and dust hood positioning (dimensions in the figure are in mm)

Dust collector power input:

The power input is 380V, 50HZ, and the equipment should be well grounded.

Dust collector compressed air input:

The compressed air input is between 0.5-0.8Mpa. The compressed air must be filtered through a dryer or air filter for oil-water separation before it can be connected to the dust collector air tank.

Control panel introduction:

The dust removal equipment should be operated by a person who is familiar with the performance and the basic principles of the control system.

1. When the power is on, press the "Start" button to blow air 01 to enter the pulse cleaning. The system digital display light shows that it will enter the next pulse cleaning cycle. Press the "Start" button to start the dust collector fan.

2. Press the "Stop" button when shutting down. If the dust collection efficiency feels poor, you can press the "Clean" button again. At this time, the fan will not start and enter the offline pulse cleaning cycle mode. After the system setting cycle is cleaned, the offline cleaning cycle mode will automatically stop.

3. Set pulse parameters: Press ‘Cycle Time’ for a short time to adjust the online cleaning cycle time of the “Startup” program segment (i.e., when the fan is running, the pulse automatically cycles to clean the dust). The parameter is generally set to 60-500 seconds. “△▽” is for digital size adjustment, and “▷▷” is for movement adjustment from the unit to the thousandth place. After setting, press “OK” to save; press ‘Cycle Time’ for 5 seconds for the pulse cleaning cycle time of the “Offline” program segment. The parameter is generally set to 10 seconds. After setting, press “OK” to save; press ‘>>’ for 5 seconds for the cleaning times. The parameter is set to about 160 times. After setting, press “OK” to save.

Causes and troubleshooting of faults:

1. Loud fan noise:

Causes: ① Fan reverse ② Fan bearing damage ③ Fan screws loosened ④ Fan power input phase loss

2. Poor dust collector effect:

Causes: ① Fan reverse ② Pulse backblowing not performed ③ Bag service life exceeds 2 years ④ Whether there is air leakage in the dust collector

3. Control panel does not display:

Causes: ① Power is not input or neutral line is disconnected ② Whether the switch power supply is damaged ③ The panel itself is damaged

4. Air switch trips:

Causes: ① Fan motor overload ② Power phase loss ③ Electrical accessories damaged ④ Dust suction port blocked

5. Pulse air leakage:

Causes: ① Pulse diaphragm damaged ② Pulse diaphragm is stuck with foreign matter ③ Pulse valve damaged

6. Thermal overload relay pops out:

Causes: ① Thermal overload relay amperage is adjusted too small or damaged ② Dust suction port blocked

Maintenance and care

1. Regularly check whether compressed air enters the gas tank, and check whether the pulse valve and air pipe are leaking. The pulse valve diaphragm needs to be replaced within 2 years of its service life.

2. Regularly check whether the power line is aging and worn, and it needs to be replaced after 3-5 years.

3. Whether the dust collector is reliably grounded.

4. Regularly check whether the electrical components in the distribution box are damaged or aging, and they need to be replaced after 2-3 years.

5. Regularly check whether the dust bag is damaged, and it needs to be replaced within 2 years of its service life.

6. Every time the filter bag is fully replaced, the dust in the box should be thoroughly cleaned.

7. The pulse valve core and spring should be cleaned regularly, and the oil should be wiped off with alcohol to prevent the core and spring from being precipitated and sticking, which makes the action inflexible. If the spring is broken, it should be replaced immediately.

Bag maintenance plan and steps

In order to ensure the safe and stable operation of the equipment, the bag must be replaced every two years according to the on-site working conditions. The maintenance content is to repair or replace the bag. Be sure to wear a gas mask or mask for maintenance. The specific steps are as follows:

1. After stopping the machine, turn off the external line switch of the dust collector and remove the power cord to ensure that there is no power before maintenance.

2. Turn off the external compressed air source, open the pressure relief port at the bottom of the gas tank, and discharge the gas.

3. Remove the pulse valve coil screw and pull out the coil, and place the screw in the container to prevent loss.

4. Remove the connecting bolts between the upper box and the lower box of the dust collector, and place the screw in the container to prevent loss.

5. Lift the upper box of the dust collector and place it on the ground (there is a lifting ear around the top), and you can see the clean air layer.

6. First remove the fastening screws and slipknots of the injection pipe in the clean air layer.

7. Slowly pull up the bag dragon frame from the middle of the bag hole. Note: If you encounter resistance, you can shake the frame gently and then pull it back until the entire frame is lifted out of the clean room.

8. Pinch the clamp ring at the mouth of the bag until it is deformed, then you can pull out the bag or put the bag down to the bottom ash box.

9. The bag should be installed in the reverse order of the above. Do not turn on electricity or gas during this process.

Equipment diagram