- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

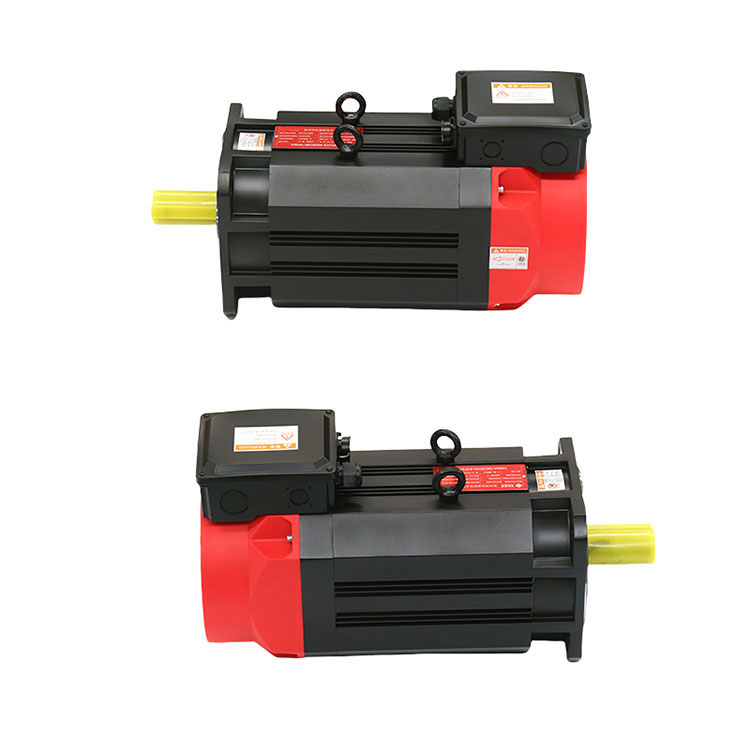

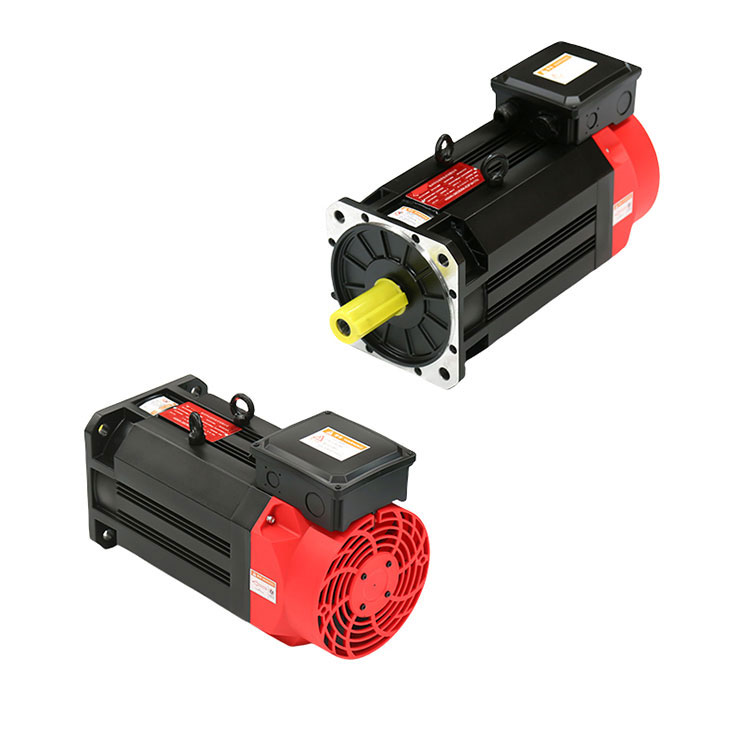

Spindle Servo Motor Induction Servo Motor

Spindle Servo Motor Induction Servo Motor is also called the executive motor, or called the control motor. In the automatic control system, the servo motor is an actuator element, its function is to transform the signal (control voltage or phase) into a mechanical displacement, that is, the received electrical signal into a certain speed or angular displacement of the motor. The servo motor has the DC and the AC points.

Send Inquiry

Spindle servo motor induction servo motor

Servo motor is also called the executive motor, or called the control motor. In the automatic control system, the servo motor is an actuator element, its function is to transform the signal (control voltage or phase) into a mechanical displacement, that is, the received electrical signal into a certain speed or angular displacement of the motor. The servo motor has the DC and the AC points.

Working principle of the spindle servo motor

Spindle servo motor is the drive motor of the spindle in the machine tool processing, which is mainly used to control the speed and position of the spindle, and to improve the movement accuracy and stability in the processing process. The spindle servo motor consists of three parts: servo motor, encoder and driver. The servo motor acts as the drive motor of the spindle load, receives the command signal of the controller, feeds back the spindle speed and position information through the encoder, and then converts the command signal into the actual motor movement through the driver.

There are two kinds of control modes of the spindle servo motor: position control and speed control. The position control is mainly through the encoder to feedback the actual position of the spindle to realize the spindle rotation accuracy and position accuracy control; the speed control is mainly through the controller output control signal to let the servo motor rotate at the specified speed to achieve the purpose of controlling the speed. At the same time, the spindle servo motor also has some special functions, such as acceleration, deceleration control, load control, torque limit and so on.

main parameter

|

Rated work RATED POWER |

5.5 KW |

stator resistance (I) STATCR RESSWCE |

|

|

|

rated voltage RATED VCLTS |

380 V |

Stator electrical resistance (X1) STATCR HEACTNCE |

|

|

|

mode of connection WODE OF OOWNECTN |

Y |

Rotor Resistance (B2) ROTOR.RESSANCE |

|

|

|

Rated frequency RATED FREQIENOY |

50 e |

Rotor Reactance (X2) RTOR REACTNE |

|

|

|

rated current RATED CURRENT |

12 A |

excitation reactance (Im) EXOTATCN FEACTNCE |

|

|

|

rating torque RATED TORQUE |

36 Nn |

Reactance ((m) ENUTN HEACTANE |

|

|

|

Benchmark speed REFERENCE SPEED |

1500 r/min |

insulation grade NSLATON CRADE |

F |

|

|

maximum speed WAX SFEED |

6000 t/me |

levels of protection LEVEL OF PROTECTON |

P:54 |

|

|

Transmission inertia WOMENT CF NERTA |

0.0151kg*m² |

number of poles POLE |

4 |

|

|

character of service RATN |

$ |

weight WECHT |

|

|

|

Cooling fan 000LN3 FAN |

Rated string RATED POWER |

34W/0.22A |

||

|

Oding voltage RATED VOLTS |

1PH 220V |

|||

|

encoder ENCODER |

Number of pulses per graph EACH LAP PLLSE NMBER |

|

||

|

Output method OUTPUT MCDE |

|

|||

|

brake apparatus BRAKE HGGNG |

name NAME |

|

||

|

Data parameters THE DATA PAEAMETER |

|

|||

2. Application of the spindle servo motor

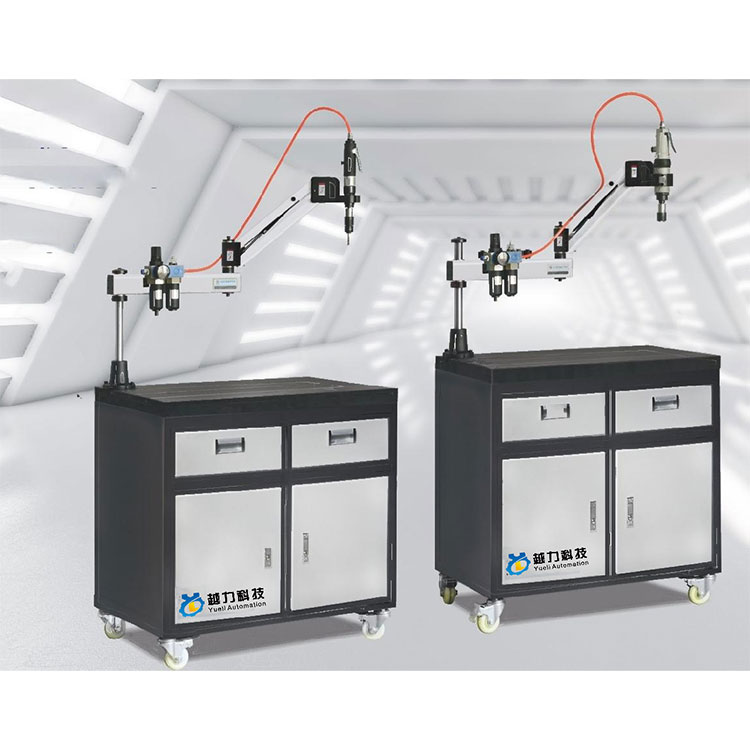

Spindle servo motor is widely used in all kinds of machine tool processing equipment, such as lathe, milling machine, grinding machine, drilling machine and other machine equipment. Its main function is used to drive the spindle, control the speed and position of the spindle movement, so that the machine tool processing process to achieve the expected precision and efficiency. Among them, the advantage of spindle servo motor is that it can quickly respond to motion control signals, provide high speed and high precision speed and position control, and have certain operation stability and load capacity.

The application of spindle servo motor can improve the precision of machine tool processing and increase the production efficiency. In the automatic machine tools, CNC machine tools and other high-precision machine tools is an essential part, to support its high-speed, high-precision processing requirements. At the same time, the spindle servo motor can also be applied in industrial automation, aerospace, medical equipment and other fields, to provide automation drive support for various industries.

3. The difference between the spindle servo motor and the ordinary motor

1. physical construction

Servo-spindle motor is a servo-motor with built-in spindle, which integrates spindle, servo motor and synchronizer. While the ordinary servo motor is only an independent servo motor, which needs to be coordinated with other mechanical equipment to achieve relevant functions.

2. control method

The servo spindle motor uses the spindle controller to control the speed of the spindle, and the servo controller to realize the control of torque and speed. The control of ordinary servo motor is mainly based on three aspects of position, speed and torque, and its control mode is more complex.

3. performance requirement

Servo spindle motor is mainly suitable for high-speed rotation and high-precision processing requirements, requiring high control accuracy, fast response speed, and for the spindle and servo motor control at the same time. The control demand of ordinary servo motor is mainly in the position, speed, torque of these three aspects have a very high requirements, need to ensure the control accuracy and performance.

4. Main schematic diagram of the servo motor

Forward and back rotation: speed error + / -1rpm, 3000 RPM acceleration and deceleration for 1 second.

Independent quasi-stop: high precision (0.03) positioning, convenient to up and down the workpiece robot.

Rigid tapping: up to 3000 RPM rigid tapping, minimum power tooth M3.

C-axis function: the separation accuracy can reach + / -1pulse, and the vehicle and milling accuracy can be as low as 0.01rpm.

Low speed heavy cutting: instant 3 times overload, ensure the stable cutting speed, suitable for casting processing.

High-speed precision machining: constant power output above 1500 RPM, stable speed, guaranteed finish.

Strong applicability: it can be used with many domestic and foreign upper machines (CNC system, PLC, etc.).

Powerful secondary development: you can customize special features according to customer requirements.

company profile

Quanzhou more force automation equipment co., LTD., founded in 2013, the company is located in the hometown of China plumbing-Fujian south, to drill composite machine, drill center, drilling milling processing center as the leading private production enterprises, is committed to serving the plumbing bathroom, fire valve, control hardware, electric hardware, aerospace, machinery manufacturing and other industries.

After many years, Quanzhou more force automation from a simple assembly manufacturing industry, developed into independent research and development, production, sales, service as one of the machinery manufacturers, now has CNC gantry guide rail grinder, boring machine, car, milling, planing, grinding and other processing equipment and a number of advanced testing instruments. With important markets and service organizations in China, the products sell well in more than 20 provinces, cities and autonomous regions, and are exported to more than 30 overseas countries. We constantly innovate and improve in our products. With easy to operate, economic, stable, high quality products, to repay the society, service users, also won the vast trust and good reputation. We are willing to work with colleagues from all walks of life to the exploration of automatic machinery and equipment!

We pay more attention to practical in products, pay attention to after-sales, technical personnel directly to the front line, improve the shortcomings of the product, excellence, to win the market quality. Customer satisfaction, is always our unremitting pursuit! In the future, we will continue to pay attention to the user needs, is willing to work together to create brilliant!

Our service

1. Reply to your inquiry within 24 working hours.

2. Experienced staff will answer all your questions in fluent English.

3. Customizable design. The UEM & UBM are welcome.

4. Our highly trained professional engineers and staff can provide exclusive and unique solutions for our customers.

5. We offer special discounts and sales protection to our dealers.

6. Professional factory: We are a professional manufacturer of all kinds of machinery, with a history of more than 20 years. Our products are of good quality and competitive.

7. Samples: If the order quantity is large enough, we can send the sample for testing within one week. But the freight is usually paid by you and is returned when we have a formal order.

8. As an honest seller, we always use high-quality raw materials, advanced machines, and skilled technicians to ensure that our products are completed in high quality and stable functions. Feel free to contact us or visit our company.