- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

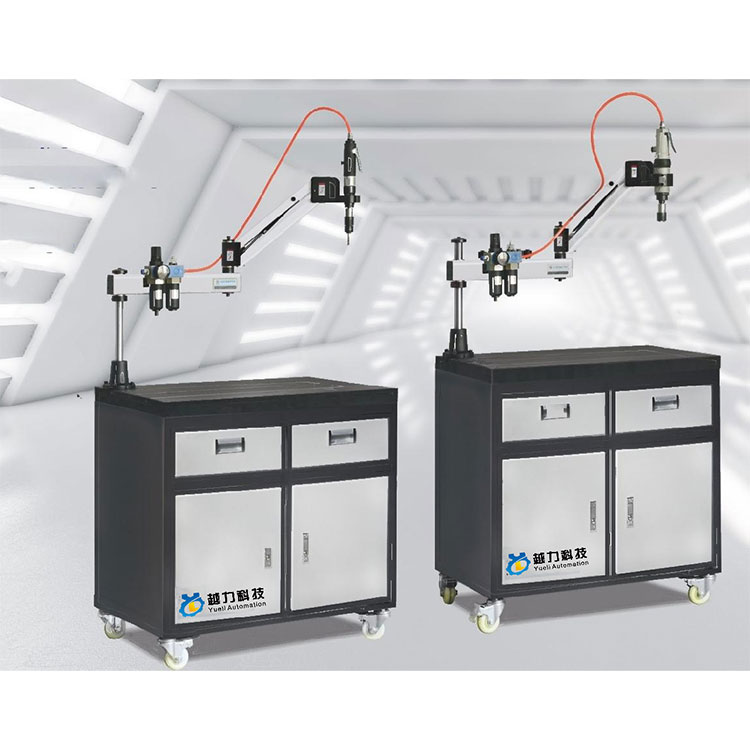

High Precision Clamp for Lathe Machine

YueLi as the professional manufacturer, we would like to provide you high quality High Precision Clamp for Lathe Machine. And we will offer you the best after-sale service and timely delivery.

Send Inquiry

High Precision Clamp for Lathe Machine features introduction

China High Precision Clamp for Lathe Machine Factory Directly Supply. YueLi is High Precision Clamp for Lathe Machine manufacturer and supplier in China.

Focus on product quality, strength to achieve the future, to provide cost-effective products

Through the unique structure and wide elasticity, the holding force of the rubber flexible chuck is 3 times that of the traditional all-steel slotted chuck. Regardless of the size of the workpiece, the clamping force is always parallel and evenly distributed on the workpiece, rather than concentrated on the front and back ends of the chuck working holes. The traditional all-steel chuck often occurs when the workpiece is greater than or less than the chuck aperture, the force point of the workpiece will be out of balance, greatly reducing the strength and accuracy of the gripper. The material between the clamps is a durable synthetic rubber that is tightly bonded by the surface of the vulcanized clamps and through the holes. Compared with the traditional spring chuck structure, it is not affected by high temperature, coolant and iron filings, and has the following characteristics:

1, chuck chuck hardness HRC60, and after cryogenic treatment, improve product accuracy and stability. The rotation runout accuracy is ±0.005MM, and the clamping range is ±0.5mm

2, durable synthetic rubber integrated structure, ensure its flexibility, and can resist the corrosion of iron filings, coolant.

3, the sealing of the rubber chuck can seal the workpiece and the machine spindle, so that the spindle is free from oil and chip damage. Can be used as a water clamp to prevent coolant overflow.

4. The clamping block is formed and ground as a whole, which has the characteristics of high rigidity and high precision.

5, due to the clamping method of parallel clamping, each clamping block will apply a uniform and accurate clamping force to the surface of the workpiece, and its clamping force is 3 times that of the ordinary spring chuck.

Comparison of clamping characteristics between ordinary all-steel spring chuck and rubber flexible chuck:

Ordinary all-steel spring chuck can only obtain the maximum clamping force when the equal diameter clamping, when the workpiece is greater than or less than the chuck aperture, the force point of the workpiece will be out of balance, which will greatly reduce the strength and accuracy of the clamping. The rubber flexible elastic chuck within a certain range, regardless of the outer diameter of the workpiece is larger or smaller, due to its parallel clamping characteristics, it will be evenly contacted with the chuck to form a balanced clamping force

|

When the workpiece is larger than the aperture |

When the workpiece is smaller than the aperture |

Rubber elastic chuck |

|

YueLi |

model |

Various brands of CNC tool feed type, turret type, and row tool lathes |

|

|

Specification |

D1.0--D100.0 |

Scope of use |

CNC lathes, CNC machining centers, gear hobbing machines, gear shaping machines, industrial special machines, etc. |

|

Material |

spring steel |

Service life |

The number of opening and closing tests under normal use conditions is not less than 1 million times |

|

hardness |

Multi-level hardness, head clamping hardness HRC58-65 degrees |

Accuracy |

Concentricity level A: rotational runout within ±0.008MM |

The advantages of the company's products

1, many years of precision chuck machine parts production experience Taiwan, Japan, a number of machine tool manufacturers supporting supply Business, many years of professional production of precision and superhard alloy collet, Guide sleeve, chuck, CNC machine tool fixture, rubber flexible clamp

Head, single crystal diamond turning tool, optical grinding arc forming tool Material clamp, dental tube, opening and closing claw, turning tool, etc.

Made with Japanese technology

Product quality is stable, high precision, good concentricity(0.005 mm). Using Japanese spring steel, with good elasticity, long service life, synthetic high quality rubber vulcanization bonding, with anti-degumming, no deformation, heat resistance, corrosion resistance Characteristics of corrosion.

Products are used in a wide range

Suitable for CNC lathe, CNC machine lathe, CAM Core type automatic lathe, industrial special machine, etc.; Special student The selection and quality control of production equipment are strictly regulated Control, stable product quality, cost reduction.

Non-standard products can be customized according to requirements

With the development, proofing, confirmation, custom production process processing as one of the enterprises. Material selection, process setting, production equipment selection and quality control are strictly controlled; Various specifications and models can be customized according to customer requirements.

Perfect pre-sale

After-sales service system

Professional service team, quick response to pre-sale, sale, sale Post-demand; Regular products shipped within 24 hours, factory price Direct sales service, no intermediate links. Intimate after-sales service Team, 24 hours waiting for your call, to provide you with a Station service.

Field of application

1. CNC centering machine lathe

2. Mechanical application

3. Core moving machine

4. Automatic lathe

5. Mechanical processing

6. Tapping machine