- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China core shooter Manufacturers, Suppliers, Factory

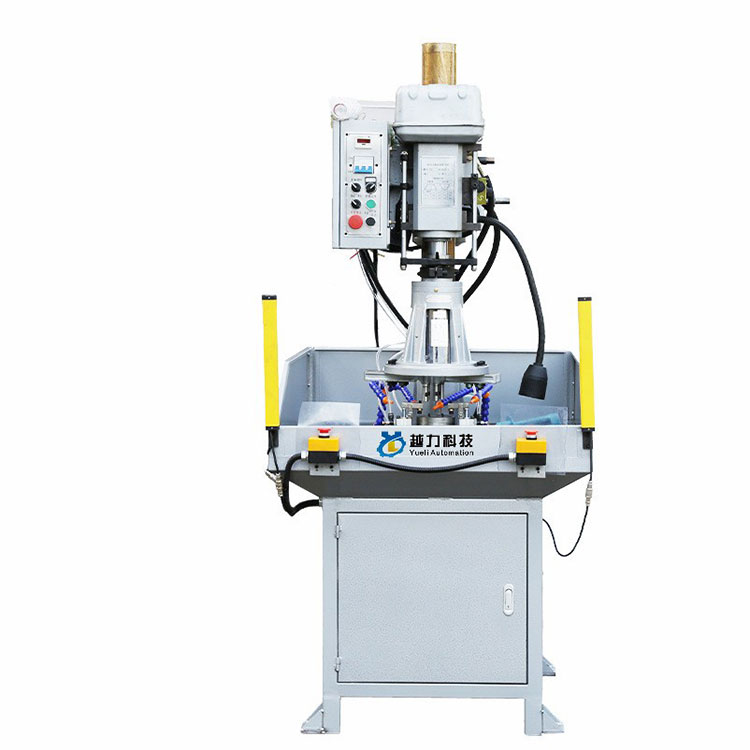

Yueli is a major in China's professional core shooter manufacturers and suppliers. Our high quality core shooter is not only made in China, but also provides quotation services. Welcome to our factory to buy products and give you a reasonable price.

Hot Products

Electric Tapping Machine

High quality Electric Tapping Machine is offered by China manufacturer YueLi. Quanzhou Yueli Automation Equipment Co., Ltd. was founded in 2013 and is located in Nan'an, Fujian, the hometown of water heating in China.Table Tapping Machine

YueLi is one of the professional Table Tapping Machine manufacturers and suppliers in China. Table 1 tapping machine appearance, a tapping machine is driven by a pair of high-precision switching gear feeding, feeding system with friction clutch, in the processing overload automatically disconnected chain drive, to ensure that the tapping is not damaged. Because it is gear driven, it is not easy to wear, strong anti-overload ability, suitable for high-frequency tapping processing. At the same time, one person can operate 2-3 Taiwan tapping machines, which can improve the production efficiency of customers.Double Open Pneumatic Flat Vise Fixture

YueLi is Double Open Pneumatic Flat Vise Fixture manufacturers and suppliers in China who can wholesale Double Open Pneumatic Flat Vise Fixture, we can provide professional service and better price for you.Manual Drilling Tapping Compound Machine

YueLi is Manual Drilling Tapping Compound Machine manufacturers and suppliers in China, we can provide professional service and better price for you. The manual working machine consists of a base, a column, a lifting table, a middle trailer, a working table and a spindle unitVice Three Axis Drilling All Inone Machine

YueLi warmly welcome you to wholesale Vice Three Axis Drilling All Inone Machine from our factory. Our products are CE certified and currently have a large amount of factory inventory. We will provide you with good service and factory discounted prices.Bench Servo Drilling And Tapping Machine

YueLi is one of the famous China Bench Servo Drilling And Tapping Machine manufacturers and suppliers. Our factory specializes in manufacturing of Bench Servo Drilling And Tapping Machine.Function features: The bench servo drilling machine is driven by double servo motors to achieve drilling and tapping processing, saving processing time and improving product accuracy. The electrical system is controlled by PLC, simple operation and low failure rate. The equipment has the characteristics of "high precision, high efficiency, automation", one set of 2-3 sets of tapping machine operation, which can double the production efficiency for customers.

Related Search

Auto Core Shooter MachineAuto Core Shooter MachineryAutomatic Core Shooter equipmentAutomatic Core Shooter MachineAutomatic Core Shooter MachineryAutomation Core Shooter MachineAutomation Core Shooter Machinerycold box core shootercold box core shooter machinecold box core shooter manufacturersCore Shooter equipmentCore Shooter Machinecore shooter machine manufacturercore shooter machine pricecore shooter machine workingCore Shooter Machineryfully automated Core Shooter Machinefully automatic Core Shooter Machinefully automatic Core Shooter MachineryIntelligence Core Shooter MachineIntelligence Core Shooter Machineryintelligent Core Shooter Machineintelligent Core Shooter Machineryshell core shooter machineshell core shooter machine workingspan core shooter machinesusha core shooter machine